Making the most of a small shop – PART 7

When I was designing my bench I envisioned it with a central dust collection system. A shop vac installed onboard was the most logical solution so I added my Bosch AdvanceVac 20 along with a simple homemade cyclone dust collector.

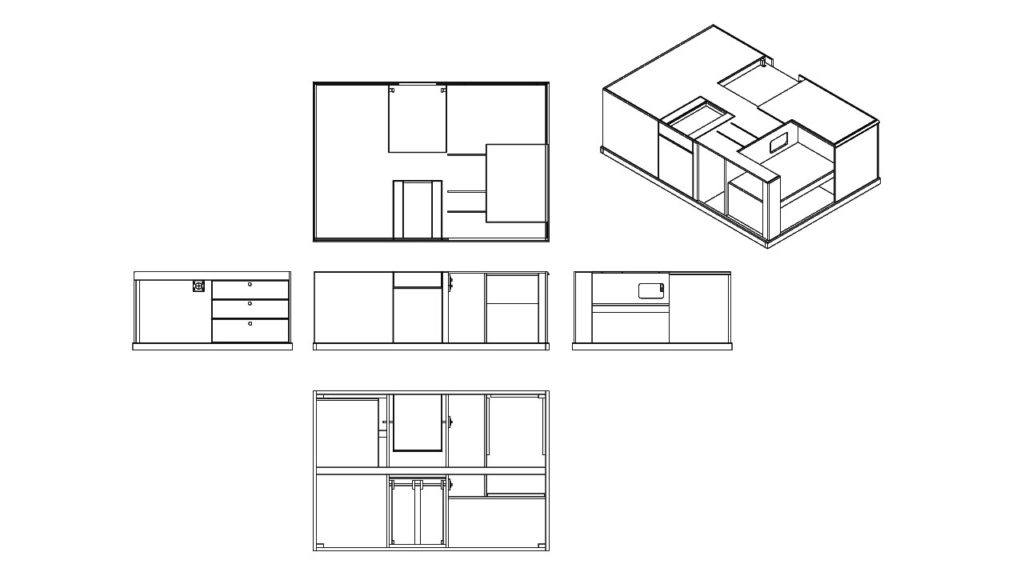

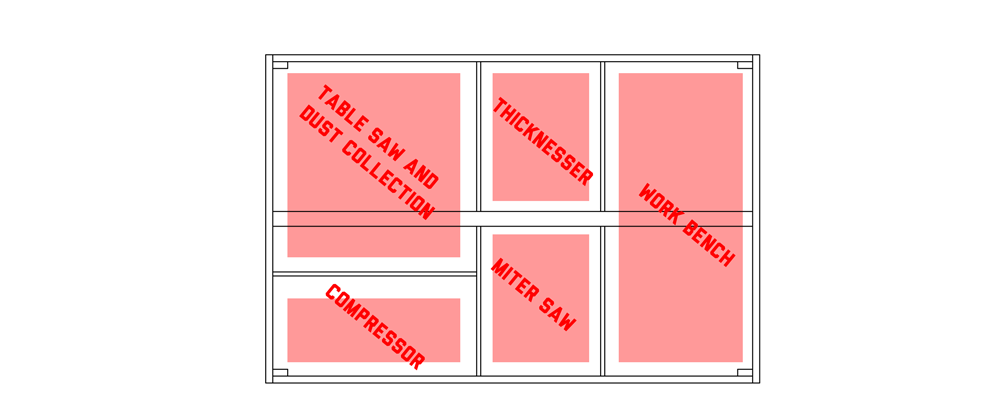

Installations already included in my All-In-One Woodworking Workstation:

- Table saw – PART 2

- Miter saw – PART 3

- Workbench with vice and power tool storage – PART 4

- Soundproof compressor enclosure – PART 5

- Rotate-to-store thickness planer – PART 6

Installation to be added:

>>>GET COMPLETE PLAN<<<

Central Dust Collector System

Installing a central dust collector to the bench involved fitting my shop vac along with my homemade cyclone dust collector in the small enclosure I allowed for it.

From there I would relay the vacuum to where it was needed using an arrangement of hoses.

One hose would be accessible at the top of the bench so it could be manually changed between all the equipment that needed it.

The other hose would be permanently connected to my table saw.

I would then install a jumper system to select between the two hoses.

In addition to this, I would make use of the built-in auto-start switch on my Bosch shop vac so I wouldn’t need to manually turn it ON and OFF when I want to use it.

PART 7: Central dust collector system

The instructions that follow are intended to be considered along with the video instructions provided by the video above.

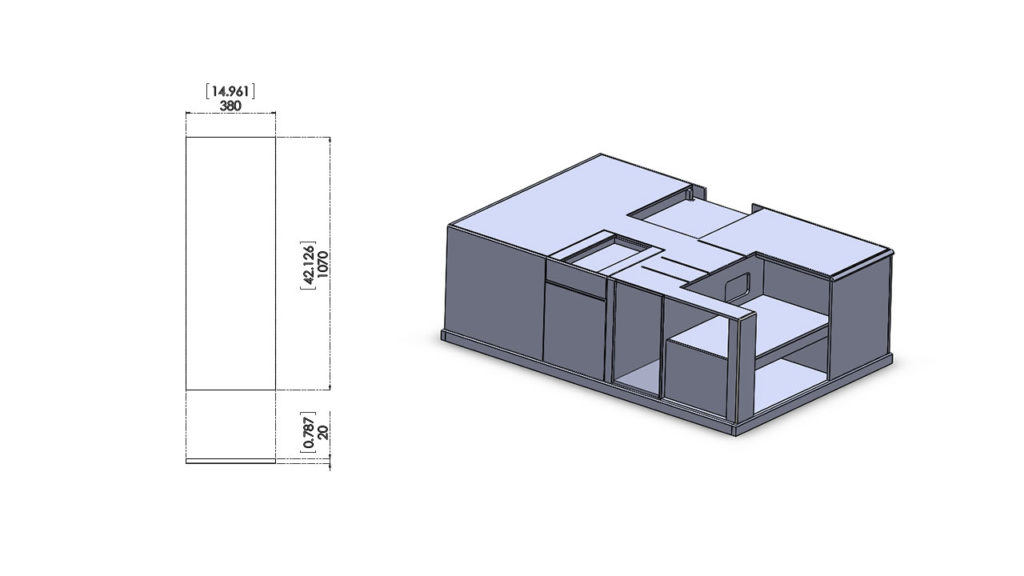

Step 1: The Base

The first step in adding my central dust collection system to my All-In-One Woodworking Workstation was adding a base to the cavity allowed for it.

This was done in the same way as in all the steps before this, by adding planks on the inside of the enclosure paneling and installing the base on top of it.

Step 2: The Pipes

Next, I installed all the fixed piping using a combination of PVC and flexible hose.

Three pipes were installed to a common point. One pipe coming from the table saw while the other was installed from the center of the bench and mounted underneath the bench top. The final pipe was run to the dust collector/shop-vac system.

At the common point, the pipes were installed inline with the suction pipe (to shop-vac) in the center.

This then allowed me to use PVC elbows as a jumper to direct the airflow from the table saw or the bench top.

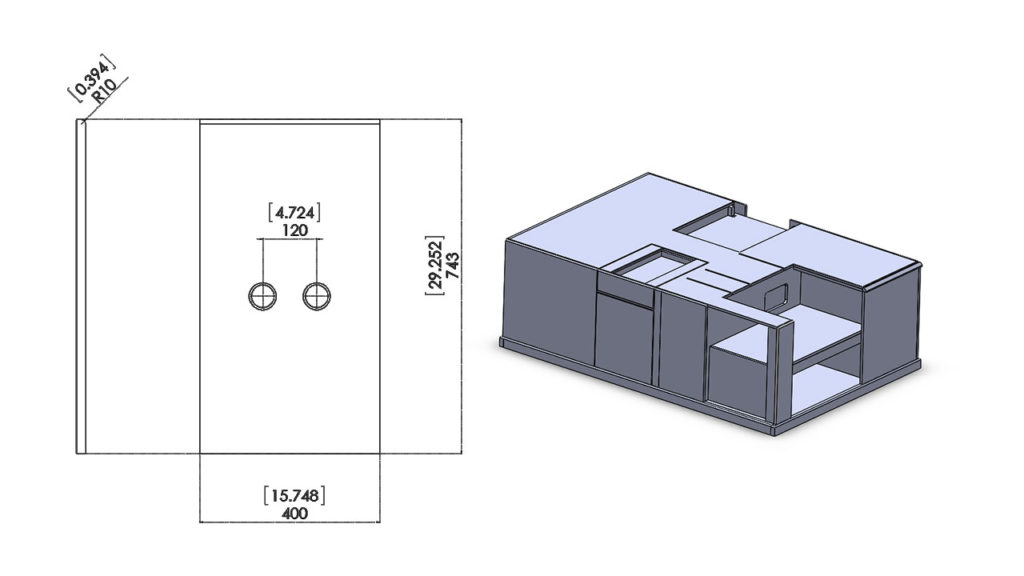

Step 3: The door

The final step was adding a door to conceal the equipment in the enclosure.

In the door, two large holes were cut to allow for adequate airflow for the shop-vac exhaust.

Extra

To increase the functionality of my central dust collector system I opted to incorporate the auto-start function of my Bosch shop-vac into my design.

To do this I powered my shop-vac from a wall socket and then used the shop-vac to power each tool that would be used together with the dust collector system.

The result was the auto-start of the shop-vac when the power tool is started.

Complete!