What is a table saw? A table saw is a very useful power tool to have in your home workshop. Used for fast and accurate ripping, cross, miter and bevel cuts into wood. The beauty of the tool lies in the quality and accuracy of the cut it produces. It does its job and it does it well but if not used correctly it will show no mercy in its retaliation which can result in serious injury or even fatality. In this article we will be looking at the dangers of the incorrect use of a table saw as well as safety procedures and available accessories to limit incidents.

But before we get into that we’ll just take a brief look at the normal operation of a table saw

Ripping: A cut along the grain of a workpiece

Table saw operation

A table saw is essentially a circular saw mounted upside down underneath a flat surface (table) with the blade protruding at an adjustable height. A 10” saw generally being able to produce 3-1/4” thick cuts at 90° and roughly 2-1/2” at 45°. The blade can be expected to run at speeds exceeding 4000 RPM (Depending on the saw model), spinning towards the operator and produces a cut when a workpiece is fed into the blade by the operator. Although table saws can be used to execute a number of different types of cuts, including cross and miter cuts, its main function remains ripping (Crosscuts ideally performed with a Miter Saw).When ripping the operator will set the fence at the desired width with respect to the blade and feed the workpiece through the saw using the fence as a guide.

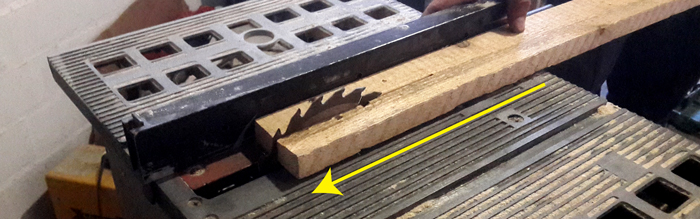

PHOTO: Workpiece being fed into blade using the fence as a guide.

NOTE: Safety accessories removed only to illiterate sawing.

REMOVING IS NOT ADVISED.

The dangers of using a Table saw

Some people would consider the table saw to be one of the most dangerous power tools in a home workshop. With the two major causes for injury being kick back or contact with the blade.

What is kick back?

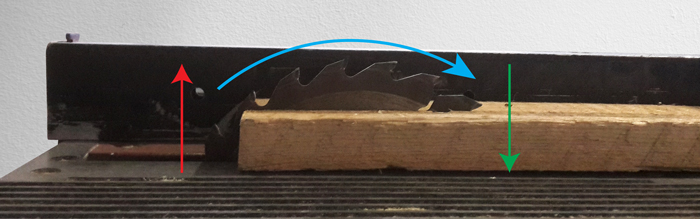

When using a table saw to saw wood you are pushing a stock through a blade spinning at 4000+ RPM in the direction of the operator (Blue arrow). With the blade effectively sawing through the workpiece in a downward direction (green arrow). But while the sawing side of the blade is spinning downward the back of the blade is spinning upwards (red arrow). As you saw through your work piece the wood will move over the part of the blade that is spinning upwards and if the blade gets hold of the wood it will throw the piece of wood in the direction the blade is turning i.e. in the direction of the operator. Now imagine the potential damaged done when a stock gets launched by a blade spinning at 4000 RPM. In short, kickback on a table saw occurs when the wrong side of the saw blade grips the stock.

When using a table saw to saw wood you are pushing a stock through a blade spinning at 4000+ RPM in the direction of the operator (Blue arrow). With the blade effectively sawing through the workpiece in a downward direction (green arrow). But while the sawing side of the blade is spinning downward the back of the blade is spinning upwards (red arrow). As you saw through your work piece the wood will move over the part of the blade that is spinning upwards and if the blade gets hold of the wood it will throw the piece of wood in the direction the blade is turning i.e. in the direction of the operator. Now imagine the potential damaged done when a stock gets launched by a blade spinning at 4000 RPM. In short, kickback on a table saw occurs when the wrong side of the saw blade grips the stock.

Preventing kick back

At this point I can imagine a few people thinking, “Nope, not for me thank you”, but the point of the article is not to serve as a deterrent but instead motivate safe operation by creating awareness of potential dangers when using a table saw.

Correctly setting the fence will be your first defense against kick back. Ensuring the fence runs parallel to the blade will lead to the workpiece moving through the blade in a straight line and so limiting the chances of the back of the blade getting hold of the wood. If the fence is set incorrectly (skew with respect to the blade) it can lead to the stock being pushed into the side of the blade by the fence effectively pinching the blade.

In addition, most modern day table saws come fitted with a riving knife. Riving knives minimize the possibility of kick back by serving as a barrier to prevent the stock from pushing skew into the blade.

Preventing contact with the blade

“Freddy four fingers use to have 5 until he took up woodworking“

At this point, I wouldn’t think it necessary to explain why you don’t want any part of your body or clothes getting in the way of the blade when the saw is running.

Most table saws have some sort of blade guard mechanism covering the blade. This is a very important safety feature and should always be used where possible.

Flesh detecting table saws – The ultimate table saw safety device

In the 1999 a man with a vision developed a mechanism that would lock up a saw blade on a table saw when any flesh came in contact with the blade. The idea was revolutionary and SawStop was born. The idea incorporates a spring loaded alloy brake that engages instantaneously when flesh contacts the blade. This is achieved by loading the blade with a small electrical signal which is monitored by an electronic control circuit. When in contact with flesh, which is conductive, the signal is distorted which in turn activates the safety brake. The only downfall is the process completely destroys the blade.

Much more recently Bosch Power Tools launched the Bosch REAXX table saw also with flesh detection on the blade. Their aim is to spare the blade incorporates small explosions to retract the blade to a position underneath the table when flesh comes in contact with it. To reset the blade the activation cartridge would need to be replaced (At a cost of $85.00).

These technologies do however come at a price as you can expect to pay from $1399.00 for a SawStop saw and $1499.00 for a Bosch REAXX.

How to use a table saw – The correct way – The safe way

So you have your workpiece that needs to be cut to size.

Start by unplugging your table saw to avoid unwanted start-up’s while setting up the saw. (This happens more often than you’d think). Set your fence to the desired width with respect to the blade making sure it is straight to avoid the stock pinching the blade. After this, you will set your blade height. Normally accomplished with the turn of a knob. The distance the blade should protrude above the stock is a matter up for debate as different opinions on this topic have been expressed. I feel you should set the blade at least double the height of the stock where possible. In this manner, the blade will be pushing the stock down onto the table when sawing.

Others feel, to limit the amount of blade exposed, the blade should be set to a point where it is only slightly higher than the piece of wood you’ll be sawing. But when doing this the blade will be pushing the stock back, needing more force to push it through the saw. And with a blade guard in place, the blade won’t be exposed anyway.

When the saw is set up plug it back in and position yourself slightly of to the side behind the saw so you are not standing in line with the blade. Rest the stock firmly against the fence with one hand and with the other, with a steady constant pace, feed the workpiece over the blade. Using a push stick is advised where possible.

Final DON’Ts…

- Don’t use gloves when operating a table saw – the glove can get caught in the saw blade.

- Don’t wear loose clothing and tie up long hair – Lose clothing and long hair can get caught in the spinning blade.

- Avoid cutting wet wood – This can increase the likelihood of kickback.

- Avoid using blunt blades – A blunt blade can cause kickback.

- Don’t stand right behind the blade when cutting – If kick back occurs you are not in the direct line of the projectile.

- Don’t use a warped or in anyway damaged blade – Not only would it result in a poor cut but greatly increase the chance of kickback.

- Always ensure after adjusting the saw that all relevant components are fixed – You would not want the blade to drop or the fence to slip while sawing

Conclusion

A table saw is a useful tool to have. Instead of a time-consuming setup with planks and clamps to set up a fence for your circular saw a table saw sets up fast and produces a neat cut. The convenience comes with the responsibility to practice safe working procedures. So be responsible, work safe and GO OUT AND BUILD SOMETHING.

Like most power tools, table saws are not toys. If used incorrectly a table saw can cause serious injury or lead to fatality. It is always important to use a table saw as instructed by the user manual and never to alter or modify the saw in any way. Always use eye protection.

Woodworkjunkie.com, DIY like a pro.

Very useful information. I was not aware of the kick back, I do not think they mentioned that one in wood work at school.

How much are good quality ones, but not the top range that you mentioned here?

Hi Hisbel

For DIY purposes you can expect to pay $250.00-$300.00 for a good quality jobsite table saw. It all depends on brand and personal preference.

I have been using a table saw for most of my life (37 years). This is a great article on the safely and use. Long ago in high school, my shop teacher and mentor showed the class what happens with kickbacks by demonstrating it. The wood he used went right through the wall. Scared the tar out of me, which was what he was going for. I learned quickly the safe way to use a table saw. I hope anyone starting out using one reads this first. Nice job!

Thank you Hillard.

Yes, table saws have their place in a home workshop but always need to be operated with caution.

I am always doing some kind of project that involves my table saw. Even with a small, inexpensive unit, you can make some great cuts. Safety is absolutely key, though, you can really get hurt if you aren’t careful. I love the quote about Freddy Four Fingers, that is classic. I like how thoroughly you explain how to properly use a table saw. Very valuable information. Flesh detection is amazing as well. What brand of table saw do you prefer, or recommend?

Yes definitely. Most of my projects start with my table and miter saws. They add quality to your projects trough accuracy. With regards to my recommendation, like with most power tools, it all depends on the intended use of the tool. Duty cycle and accuracy are my focus points when buying tools for woodworking and I’m pretty much sold on warranties. A warranty is a indication of a manufacturers confidence in their product. If I had to be brand specific I would recommend Bosch for professionals and Skil for DIY.

Hope that’s helpful.

Thank you for writing this helpful saw safety article! I am in the process of building my very first coffee table with slab wood. I am going to use my friend’s saw table in a few weeks and I have to say that I’ve been very nervous. I’ve never used one before. It’s most likely that my friend will operate it for me, but I actually really want to learn how to use it (in a safe manner). I’m definitely going to review these tips before we get started!

Hi Audrey.

Just like you I was nervous around a table saw when I first started using one. Since then I have learnt that following procedure and execution with confidence is key. If you’re using a saw like this for the first time it is definitely a good idea to do so under supervision.

Good luck with your coffee table. Remember good preparation leads to great execution.

I have seen so many time of this table saw, sometimes would see it in horror movies or action movies. ^^ haha. That’s would be great for doing a woodwork. Great post

Hello and thanks for sharing, Gone are the days when we had to do things manually now in this day and time we have all the power tools that we can think off and still there are more that is yet to be invented. Saying that though we have to be careful with these tools because there are many persons that have gotten injury with these tools while using them. Thanks for writing this post with all of this good information, it is well detailed and easy to follow.

I was wondering if there is a reason why a table saw does not have a simple device between the guide and blade that would protrude down upon the piece of lumber being cut. Like a adjustable peg with a roller on it. Perhaps two of them spaced apart the length of the blade.

Would this not keep the kick back from happening as it would hold the lumber down?

Hi Marcus.

What you are explaining does exists. Some blade guards offers this function. But it will not eliminate kickback. It does however prevent the wood from flying up towards the operator when kickback occurs.

Jean

Thanks for the information here on table saws. I see that table saws are great for cutting wood, in particular ripping along the grain. You specifically mention to be careful of a blunt blade which makes sense. How do you keep an eye out for a blunt blade, and is there a way to sharpen them? Or do you just need to buy a new one when the blade dulls?

Hi Graig,

Noticing a dull blade is something that takes a bit of experience but there are some things to look out for. A blunt blade will start sawing slower but in addition, will cause more wood burn than usual. You will also start noticing more uneven cuts due to things like tear out.

Often cleaning a dull blade can restore its edge but this is also a practice that can only be repeated a number of times.

Attempting to sharpen a blade a something I would not advise as it is something that takes years of experience. Just replacing is much less labored.

Hope this is helpful.

Jean

My friend lost a finger because he wasn’t careful while he was using a table saw. Still, he uses it for everyday work. So I agree with the last sentence of an article, safety comes first.

Hi,

Unfortunately, this a story is one I’ve heard before. Woodwork Junkie places a great deal of emphasis on safe work practices.

Safety first!

Jean

Great tips on table using a table saw, I used to work with wood myself making furniture in my basement during the winter months. I learned the hard way about the various dangers of wood working machinery, I only wish I knew the tips you shared in this article back then.

Is there any particular table say you recommend for people looking for this tool as a hobby, there are so many to choose from and it can be overwhelming?

This is true. I also had a hard time making up my mind when I was buying my first saw. Though the Dewalt jobsite saw is a favorite for many hobbyists, I would lean more toward the Rigid when just starting out. It is a good quality, value for money saw.

Hope this is helpful.

Jean

A great piece of information. I think this is what I was exactly looking for. All tips in a single click. I would definitely try to follow these suggestions. I really enjoyed this post and I hope you will keep posting this kind of post in future.

Hi I found your video on YouTube.

Tools in SA are expensive. When I travel I try to bring some back with me if I can.

I see your links to tools are to Amazon UK.

Do you buy from them?

I find Amazon USA cheaper, but often don’t ship to SA.

Have you found a soulution?

Any thoughts on the Dewald Job Site saw with rak and pinion fence as an alternative to the one you have?

Thanks

Hey Craig.

The site actually links to both Amazon and Amazon UK. Personally, I use both.

I do find Amazon.com cheaper but I can’t shop electrical components and tools from there as they stock 110V as opposed to the 220V we have here. It is, unfortunately, tricky to find a supplier that ships to SA.

The Dewalt DW745 is a better saw than the MLT 100 (in my opinion) but costs a bit more. My favorite, however, is the Bosch GTS 10 XC. At the end of the day, I guess it’s about personal preference in relation to what a person can afford.

Cheers

Jean