Cordless is convenient

Sacrificing a little torque allows us to cut the cord and end up with an on-the-go portable power tool. Yes, cordless is convenient but the convenience does, unfortunately, come with a drawback.

Batteries

Cordless power tools operate with DC voltage supplied from a battery and unfortunately, the brains of the world are yet to develop a battery that can last forever.

Though battery technology has experienced some major advances in recent years they can still only survive a certain amount of charges and discharges.

This means that sooner or later the batteries will fail and when they do your favorite little cordless drill becomes a novelty item.

The scene of a lonely cordless drill on a shelf covered in dust, untouched for months because the batteries have quit while the drill still had a lot to give, is one I’ve witnessed one too many times.

To avoid this scenario many find themselves considering whether to replace or repair the faulty cordless drill battery.

Consider the deal below

The Makita XPH102 18V LXT along with a 3Ah battery, charger and carry case.

Good deal right? Yeah, that’s an awesome deal but what if, for whatever reason, the battery had to quit? You will be forking out about $65-$70 for a replacement because it’s a 3Ah while the pricing on the charger is not that impressive either.

That’s only 40% less than original retail price just for the battery.

The same can be said for all the major brands. Dewalt, Bosch, Milwaukee, or even Ryobi.

Replacement batteries, Li-ion or Nicad, are going to cost you.

What are your options?

- Buy new batteries

- Re-pack the batteries

- Convert the tool to a coded version

- Or buy a complete new cordless drill kit

Buying replacement batteries

While this is the obvious and easiest solution for many, it is definitely not the cheapest. For a 18V 2Ah battery, you can expect to pay +/-$50.00 for a lithium 2 pack and +/-$35.00 for a Nicad 2 pack on the lower end of the spectrum. Considering the example above, you are better off just buying a whole new cordless drill kit.

Alternatively, you can buy a drill set of the same make and model that includes two or three batteries and use one of the extra batteries to power the old cordless drill. That is if the model you own is still available for purchase and has not been discontinued.

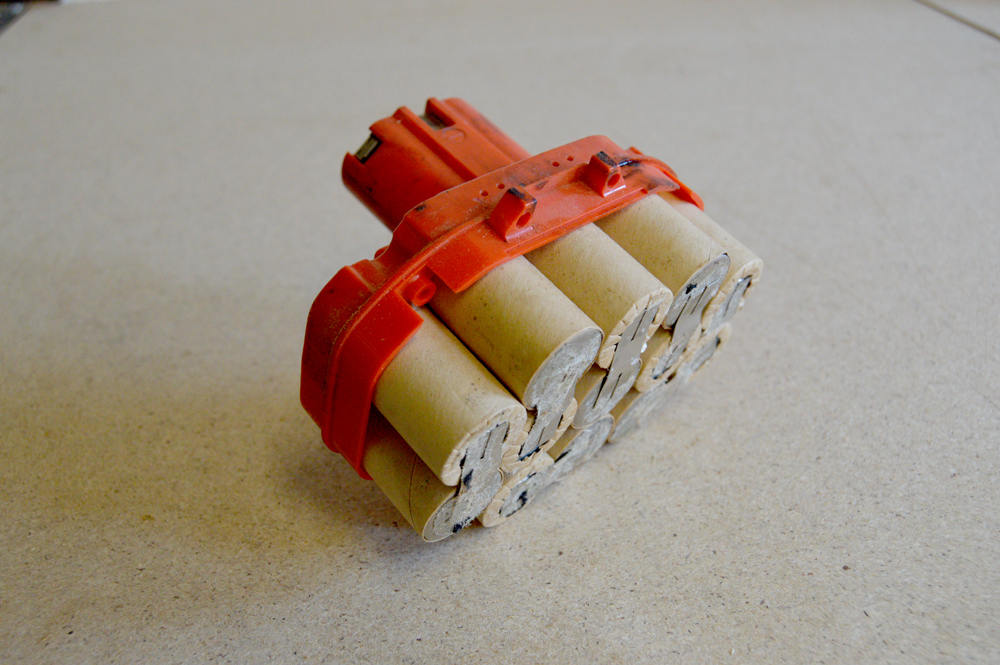

Re-packing

This is, unfortunately, only an option in the case of Ni-cad batteries.

This is, unfortunately, only an option in the case of Ni-cad batteries.

It involves stripping open the old battery, removing the damaged cell, and installing new ones.

Ni-cad cells are 1.2V which means to repair a single 18V battery would require 15 cells. They are then connected in series with bridge plates to make up a single 18V battery.

The downside?

It requires a bit of know-how and the effort is not justified by the minor saving as the cells alone are not much cheaper than buying a complete battery.

15 Nicad cell generally retails in the $30.00 region and up.

Convert to corded and power from a wall socket outlet

If you are brave enough and have the electrical know-how you can consider converting the drill to a corded version of itself. This would allow you to still be able to use the drill while sacrificing the convenience of it being cordless.

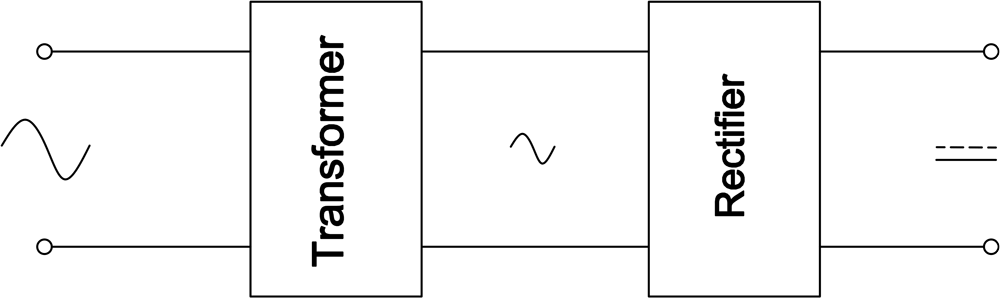

To run a cordless tool from the electricity supplied by a conventional wall socket the AC needs to be rectified to DC (rectifier needed) and the voltage stepped down to a voltage in the region of the operating voltage of the cordless tool (Transformer needed).

More importantly, you will need to supply the tool with enough current for it to operate at its full capacity which, depending on the drill, can be as much as 7A or even more.

Jean, you are doing amazing things! Thank you for making your genius available to me in Arizona, USA- all the way from South Africa! I completely agree with your drill battery assessment, and yet the economist in me keeps seeking for a more economical way to replace rechargeable battery packs. Maybe we need to boycott the battery industry until they come up with a solution that doesn’t gouge the consumer for replacement batteries.

Hey mate,

Love your vids, but Im inclined to disagree with chucking out a perfectly good drill just because the battery has died. Seems a bit wasteful.

(its 2020 now, when this comment is getting posted) I am well and truly involved in the tool/battery/charger platform, where you can buy each of the items individually and, sometimes, as a “kit”.

There are different tools and differing price points and qualities of these platforms. Ryobi for the budget concious and those of us who’ll never need such high quality equipment. Makita are a little more advanced but are also better quality. Then you’ve got Milwaulkie, and the seemingly bomb proof, tradie level, DeWalt with their flexvolt range providing everything up to amd including battery powered jobsite saws.

And those are only the names I can immediately think of. I’m sure there are plenty more.

You just buy the component that you need and this range could bebatteries, single or multi-chargers (even 12v chargers for those who are vehicle based) , different capacity batteries (in Ah), and then you’re just adding to your tool tally.

There are 2 beauties of this system. Firstly, no matter how many tools you own, they all use the same battery. This means that, when you add to your tool collection, the amount you’re paying for a tool, tends to epbe around the value of the tool. You’re not including the cost of another battery or charger.

The second point in favour of this is that you need far fewer chargers and batteries than the number of tools. I have 12 tools running off 4 batteries and 1 electric multiport charger and one 12volt charger. Ive not yet been in a position where Ive had all 4 batteries out, and with a 2 hour quick charge time, I’ve never run out of juice.

There is one drawback, though. You are then stuck with whichever platform youve invested in. If another tool, by another manufacturer, is better or even doesnt exist in your catalogue of tools, then its not easy to change.

I would never put forward a brand above another, there are clear price points and customer levels in mind, and that will depend on the individual’s circumstance,but the advantages are clear, no matter which platform you do adopt.

Unless you are using your C/less 24/7 buy a smaller pack and recharge more ..The batteries only have a certain shelf life so if you have 6 AH sitting on the workbenches weeks on end you better to buy a smaller..

cant wait for the cordless extension lead to come out.