Fluorescent to LED

Adequate lighting is a cardinal component of shop safety. Filling a workshop with light will increase visibility and can decrease the risk of accidents.

Fluorescent lights are generally the go-to for a workshop because you can fill quite a large area with light by using them. Unfortunately, fluorescent lights aren’t without their drawbacks.

- Fluorescent lights require a number of components to operate which makes troubleshooting more difficult.

- Fluorescent lights generate a lot of heat making them less energy efficient.

- Fluorescent lights are filled with toxic mercury gas which poses a health risk.

- Disposing of used fluorescent tubes requires caution.

If you have a fluorescent light installed around your house or workshop it will likely be one of two configurations.

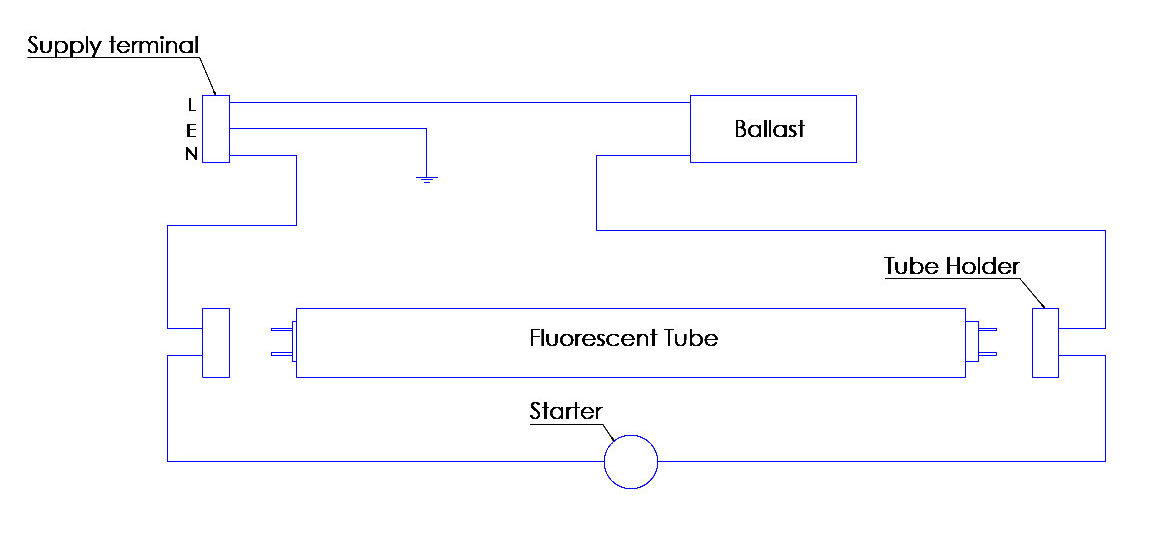

The first is the conventional configuration which makes use of a ballast and a starter.

Conventional Fluorescent light wiring diagram

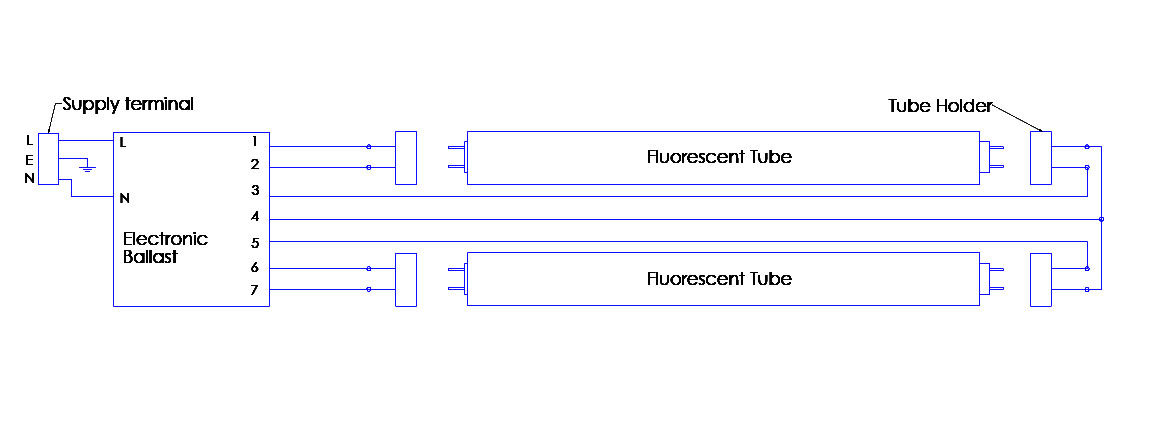

The second is the more modern solution which makes use of an electronic ballast and does not require a starter.

Modern fluorescent light with electronic ballast

LED tubes for fluorescent fixtures

The solution to all the negatives of fluorescent lights lies in the development of LED lights.

LED tubes are designed to be replacements for normal fluorescent tubes as they look very similar physically and can fit in the same fixtures.

However, despite the physical similarities, LED tubes have all the components they require to operate built into the tube.

This means that they don’t require a ballast and starter and can be supplied at one end with a Live (L) and Neutral (N) directly.

The end of the LED tube that needs to be supplied with power is indicated with an “L” and “N“.

The prongs on the other end have no electrical function and are merely there to allow the tube to fit inside a fluorescent light fixture.

Converting a Fluorescent light fixture to accept LED tubes eliminates all the drawbacks of using conventional Fluorescent tubes.

- No additional components.

- Generates very little heat – Higher efficiency.

- No toxic gas.

- In the case of plastic tubes, no special care is required when disposing of used tubes.

Because of the difference between the two tubes (Fluorescent and LED) some modification is required to enable a fluorescent light fixture to accept LED tubes.

Converting fluorescent lights for LED tube replacement

SAFETY FIRST!!

If you are not confident or competent enough to do the following then don’t. Electricity is dangerous!

NEVER attempt work on live circuits. ALWAYS turn electrical supply OFF first.

Step 1: Remove unnecessary components

As mentioned before, LED tubes already have LED drivers built into the tubes which means that to power up an LED tube requires it to be supplied with a Live and Neutral (AC) only. Making the ballast/starter and electronic ballast configurations obsolete.

This is why the first step in converting a fluorescent light fixture to accept LED tubes is to remove the unnecessary components.

Once these components have been removed you should be left with the fixture housing and lamp holders only.

When cutting the wires to remove the unnecessary components it is important to leave some wire attached to the lamp holders as these wires will be used to supply the LED replacement.

Step 2: Supply tube with Live and Neutral

Because LED tubes are designed to fit in a normal fluorescent holder you need to connect the holder to a Live and Neutral. The holder will then deliver the power to the light when the tube is inserted into the holder.

Each tube holder will have two wires. Sometimes they are color coded and sometimes they aren’t. This doesn’t matter.

Either of these wires can be selected to connect the Live to while the remaining wire will be connected to Neutral.

The easiest way to do this is to connect the power supply coming into the light fixture from the light switch straight onto one of the lamp holders using strip connectors or ferrules. The other lamp holder will not be connected to anything and will simply hold the tube in place when fitted.

After closing the light fixture the modification would be complete. A LED tube can then be inserted into the fixture while ensuring the correct orientation.

A simple alternative with no rewiring

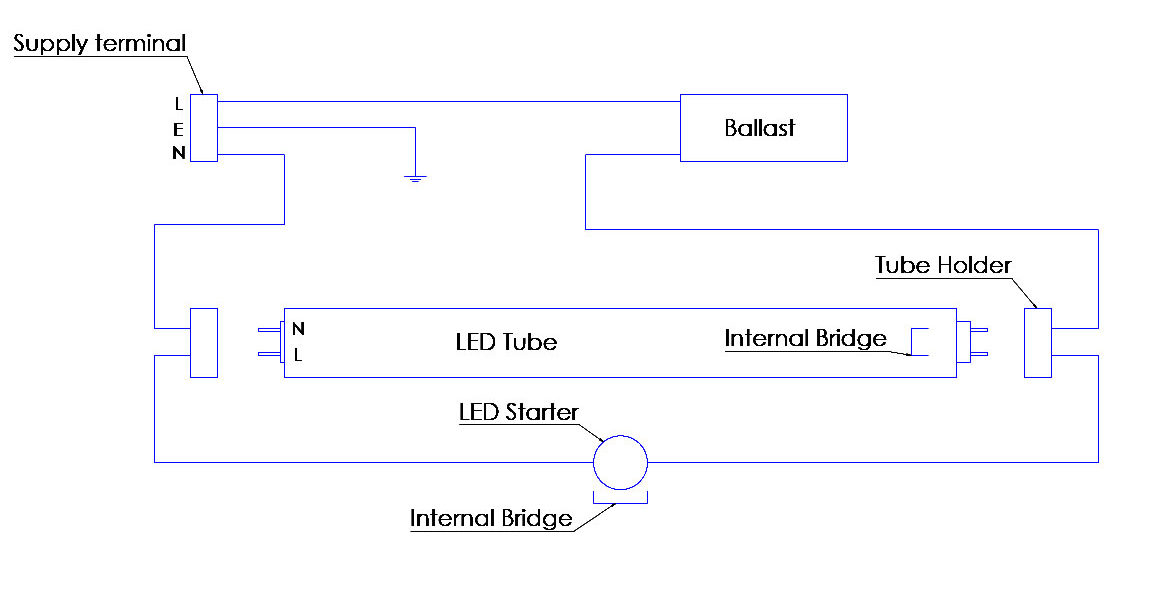

There is, however, a very simple alternative to the method described above but unfortunately can only be implemented on a conventional fluorescent light and not on one with an electronic ballast.

Recently, LED tube manufacturers have started adding components to LED tubes that would allow them to operate in conventional fluorescent light fixtures without having to re-wire the fixture.

This was achieved by adding a bridge/fuse to the unused prongs on the LED tube. The manufacturer would then also supply an LED starter with the tube which also simply contained a bridge/fuse.

When considering the first (above) wiring diagram of a conventional fluorescent light fixture it can be noted that with these bridges the Live would be routed from the opposite end of the tube to the required point on the LED tube.

Though this is a much simpler conversion I personally try to avoid it.

The downside to this simpler method is the fact that the ballast remains in the circuit and creates an unnecessary load.

At the very least I would short out the ballast if using this method.

New 1200mm led tube wired live and neutral one end when turned on trips safety switch on my 4outlet extension box have 5 tubes all do the same l thinking tubes are faulty makers say to remove ballast have done all this what do you reckon. Thankyou

Hi,

If you are supplying the tubes directly with a Live and Neutral I really can’t think of anything other than faulty or incorrect voltage tubes. The trip switch can be faulty but you could easily check this using a different load. I can tell you what happened to me once. I took down my light fixture so I could move it. When I put it back up I placed the LED tube in the holder the wrong way around. Instead of having the supply end of the tube on the Live end of the fixture I had it the other way around.

Now, as I indicated in the drawings above. The opposite end is bridged/fused so when I placed the tube in the fixture the wrong way around I creating a short circuit which tripped my overload protection switch.

Maybe you can send me some pics of the setup so I could have a better understanding of what you are working with. admin@woodworkjunkie.com

I hope this info is helpful.

What kind of tubes are you using, I bought 120VAC T8 LED tubes and hooked it up just like the diagram, I’ve checked the voltage at the tube holders and it is 120VAC. I tried swapping the tubes and nothing works.

Hey,

The ones I use operates in a range. 120VAC-220VAC. My countries supply voltage is 220VAC. The concept remains exactly the same for both voltages. If you are supplying your light with 120VAC and it is a 120VAC LED tube it should work. Make sure the tube is orientated correctly and that the light and holder aren’t damaged.

Hope this helps.

Hi,

Quick question… What were the light fittings and components you used in this video please? https://youtu.be/X319xohQg5w

Hi,

You can find the lights on my Amazon store. http://www.amazon.com/shop/woodshopjunkies

In reverse, can I use the modified LED tube light with the build-in bridge/fuse to an already re-wired light holder, i.e the L & N is on one end only?

You can but make sure to insert the tube the correct way around. If you place the fused side of the tube on the supply end of the fitting you will create a short that will burn/trip your main supply fuse/breaker.

When converting a T12, 4ft florescent lamp (non-shunted tombstones) to a LED lamp, and rewiring so that one end of the fixture is hot and the other is ground what type of LED bulb to is recommended and do I need a separate led driver?

I had some different LED tubes for replacing fluorescents, F20T12 (24″) with inductive ballast and starter. These use live at one end and neutral at the other, only requiring removal of the starter from its socket which is to be left empty. Bypassing the ballast is optional.